Tooling Inserts for Back Turning

High Performing Back Turning Inserts

- Insert design result in low radial forces

- Produces better roundness on the component

- Keeps the desired size longer without adjustment

- Chip is curled before it hits the already finished shoulder

- Good chip-control by curling the chip away from the

surface

|

- Positive cutting rake improves production and tool-life

- Only a narrow parting off insert is required in order to clean

up the non finished cylindrical diameter

- The final diameter is produced only 1 mm from the side of the

insert and tool holder, or away from the guide bushing, resulting in

good stability even when small diameters are produced

- Small distance from the side to end of wiper which makes final diameter. Very suitable for small diameters.

|

Back Turning Insert Guide

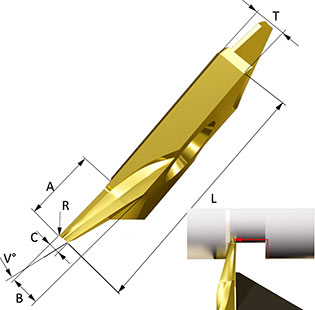

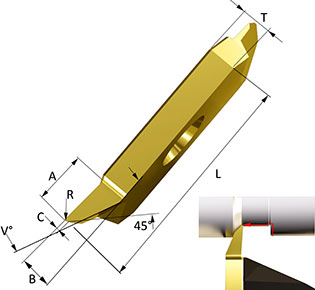

Style C

Style C is used when there is an undercut required. |

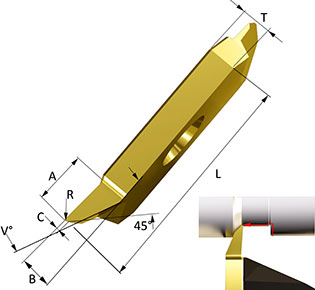

Style BT

Style BT inserts has a chamfer on the leading corner that improves the tool-life in harder materials. This insert is suitable when the wear on the style B insert is found in an early stage. |

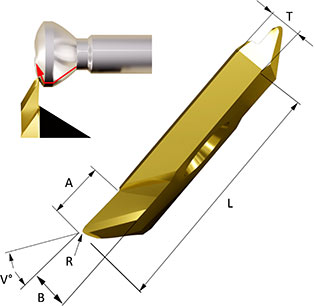

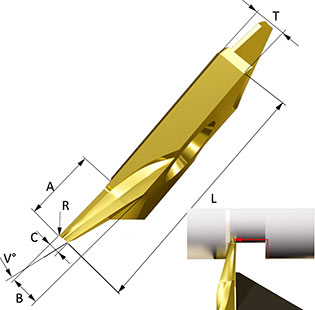

Style B

Style B is for general use in back turning applications in stainless steel, titanium, nimonic,

hastaloy, high temperature alloys, alloyed steel and other hard

and long chipped materials where good chip control is needed. |

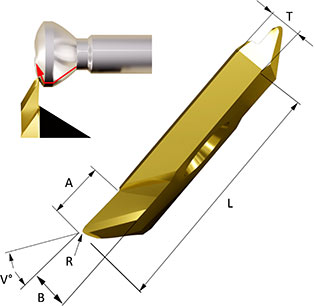

Style VLR

Style VLR is used for backturning when a smooth surface is needed when profiling. It is for example excellent to go in behind the head of a bone screw with. |

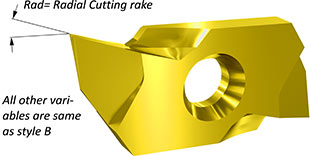

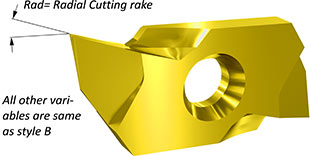

Style BP

Style BP is used for sticky materials when there is a chance of an edge build up that can spoil the surface finish or reduce tool-life. |

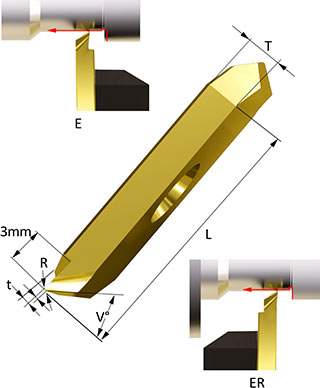

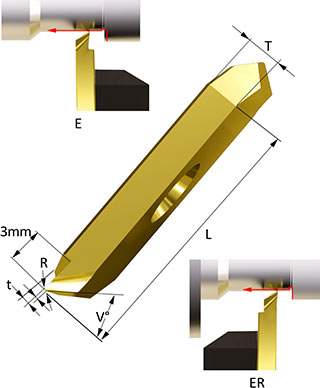

Style E

Style E is used for fine turning, using high cutting speed and low feed rate. This insert will give the best possible surface finish. By protecting the radius with the chamfer the tool life is extended compared with conventional full radius inserts. |

Style B | Inserts for Back Turning in steel and other

hard and long chipped materials

| |

|

|

|

|

|

CUTTING

RAKE

° |

STOCK |

Price

Group |

| INSERTS |

A |

B |

C |

R |

V° |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| K11ER/L B12-2-0 |

2 |

1 |

0,4 |

0 |

15 |

12 |

a |

k |

b |

b |

- |

- |

A8 |

| K11ER B12-2-05 |

2 |

1 |

0,4 |

0,05 |

15 |

12 |

r |

k |

r |

r |

- |

- |

A9 |

| K11ER/L B12-3-0 |

3,5 |

1,5 |

0,6 |

0 |

15 |

12 |

a |

k |

b |

b |

- |

- |

A8 |

| K15ER/L B12-2-0 |

2,5 |

1,3 |

0,5 |

0 |

15 |

12 |

a |

k |

b |

b |

- |

- |

A8 |

| K15ER/L B12-4-0 |

4 |

1,9 |

0,7 |

0 |

15 |

12 |

a |

k |

b |

b |

r |

r |

A8 |

| K15ER/L B12-4-05 |

4 |

1,9 |

0,7 |

0,05 |

15 |

12 |

a |

k |

b |

b |

- |

- |

A9 |

| K15ER/L B12-4-1 |

4 |

1,9 |

0,7 |

0,1 |

15 |

12 |

a |

k |

b |

b |

r |

r |

A9 |

| K15ER/L B12-4-2 |

4 |

1,9 |

0,7 |

0,2 |

15 |

12 |

a |

k |

b |

b |

r |

r |

A9 |

| K20ER B12-7-0 |

7 |

3,2 |

1,3 |

0 |

15 |

12 |

r |

k |

r |

r |

- |

- |

A28 |

| K20ER B12-7-2 |

7 |

3,2 |

1,3 |

0,2 |

15 |

12 |

r |

k |

r |

r |

r |

r |

A29 |

|

|

Style BP | Inserts for Back Turning in Sticky Materials

| |

|

|

|

|

|

Cutting rake° |

STOCK |

Price Group |

| INSERTS |

A |

B |

C |

R |

V° |

Ax |

Rad |

8M |

F8 |

B8 |

NF8 |

ND8 |

| K15ER BP12-2-0 |

2,5 |

1,3 |

0,5 |

0 |

20 |

12 |

14 |

r |

r |

r |

- |

- |

A8 |

| K15ER BP12-2-03 |

2,5 |

1,3 |

0,5 |

0,03 |

20 |

12 |

14 |

r |

r |

r |

- |

- |

A9 |

| K15ER BP12-2-05 |

2,5 |

1,3 |

0,5 |

0,05 |

20 |

12 |

14 |

r |

r |

r |

- |

- |

A9 |

| K15ER BP12-4-0 |

4 |

1,9 |

0,7 |

0 |

20 |

12 |

14 |

r |

r |

r |

- |

- |

A8 |

| K15ER BP12-4-1 |

4 |

1,9 |

0,7 |

0,1 |

20 |

12 |

14 |

r |

r |

r |

r |

r |

A9 |

| K15ER BP12-4-2 |

4 |

1,9 |

0,7 |

0,2 |

20 |

12 |

14 |

r |

r |

r |

r |

r |

A9 |

|

|

Style BT | Inserts for Back Turning in Tough Materials for Longer Tool Life

| |

|

|

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

A |

B |

C |

R |

V° |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| K15ER BT12-4-2 |

4 |

1,9 |

0,7 |

0,2 |

15 |

12 |

r |

k |

r |

r |

r |

r |

A9 |

| K20ER BT12-7-2 |

7 |

3,2 |

1,3 |

0,2 |

15 |

12 |

r |

k |

r |

r |

r |

r |

A29 |

|

|

Style VLR | Inserts for Back turning Profiles

| |

|

|

|

|

|

Cutting

rake° |

STOCK |

PRICE

GROUP |

| Insert |

A |

B |

R1 |

R2 |

V° |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| K15ER VLR12-04 |

3 |

1,0 |

0,04 |

0,04 |

35 |

20 |

r |

K |

r |

r |

- |

- |

A7 |

| K15ER VLR12-05 |

3 |

1,9 |

0,05 |

0,05 |

35 |

20 |

r |

K |

r |

r |

- |

- |

A7 |

| K15ER VLR12-08 |

3 |

1,9 |

0,08 |

0,08 |

35 |

20 |

r |

K |

r |

r |

- |

- |

A7 |

| K15ER VLR12-12 |

3 |

1,9 |

0,1 |

0,2 |

35 |

20 |

r |

K |

r |

r |

- |

- |

A7 |

| K15ER VLR12-15 |

3 |

1,9 |

0,15 |

0,15 |

35 |

20 |

r |

K |

r |

r |

- |

- |

A7 |

| K15ER VLR12-2-28 |

3 |

1,9 |

0,2 |

0,2 |

28 |

20 |

r |

K |

r |

r |

- |

- |

A7 |

| K15ER VLR12-2 |

3 |

1,9 |

0,2 |

0,2 |

35 |

20 |

r |

K |

r |

r |

r |

r |

A7 |

| K15ER VLR8-2 |

3 |

2,0 |

0,2 |

0,2 |

42 |

8 |

- |

- |

- |

- |

r |

r |

A7 |

| K15ER VLR8-2L |

6 |

2,0 |

0,2 |

0,2 |

42 |

8 |

- |

- |

- |

- |

- |

r |

A7 |

| K20ER VLR12-2 |

9 |

3,4 |

0,2 |

0,2 |

35 |

20 |

r |

R |

r |

r |

r |

r |

A27 |

|

|

Style C | Inserts for Back Turning when there is an

undercut requested

| |

|

|

|

|

|

Cutting

rake° |

STOCK |

PRICE

GROUP |

| INSERTS |

A |

B |

C |

R |

V° |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| K11ER C0-1-0 |

1,3 |

1 |

0,2 |

0 |

30 |

0 |

r |

k |

r |

r |

- |

- |

A6 |

| K15ER/L C0-3-0 |

3 |

1,9 |

0,2 |

0 |

20 |

0 |

a |

k |

b |

b |

r |

r |

A7 |

|

|

Style E | Inserts for an Extra Finishing Cut; Back Turning

| |

|

|

|

|

|

|

Cutting

rake° |

STOCK |

PRICE

GROUP |

| INSERTS |

MAX CUT |

C |

t |

R1 |

R2 |

V° |

8M |

F8 |

B8 |

| K15ER ED16-05-15 |

0,8 |

0 |

0,6 |

0,05 |

0,15 |

30 |

16 |

r |

r |

r |

A8 |

| K15ER ED16-1-2 |

0,8 |

0 |

0,5 |

0,1 |

0,2 |

30 |

16 |

r |

r |

r |

A8 |

| K15ER ED16-18 |

0,8 |

0 |

0,6 |

0,18 |

0,18 |

30 |

16 |

r |

r |

r |

A8 |

| K15ER EN16-01-0 |

1,3 |

0,12 |

0,6 |

0,01 |

0 |

45 |

16 |

r |

r |

r |

A8 |

Please note: Fine turning

insert. Maximum depth of cut in one pass is 0,08mm.

|

|

|

More Insert Information: Grades of Carbide Recommended Cutting Data

| Inserts to be used with K-type Toolholder |

L

11

15

20 |

T

2,5

2,1

3,5 |

|

Stock status

a = Stock standard in ER and EL

b = Stock standard in ER; EL against inquiry

c = Stock standard in EL; ER against inquiry

r = Stock standard in ER only

l = Stock standard in EL only

k = ER and EL against Inquiry |

|