Inserts for Parting Off

Parting Off - Selecting the Right Tool

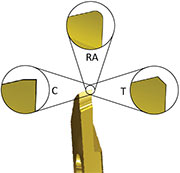

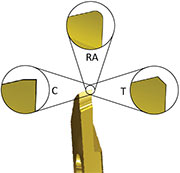

1. Axial Relief vs Component Possibilities

- Style P: 0° gives the strongest tool. Suitable with use of sub spindle. Style PS can be used for extra stability.

- Style Y: 6° gives a strong tool but can leave a small chamfer if a sub spindle is not used.

- Style Z: 15° is an all-round parting off insert. It can be used without a sub spindle.

- Style S, U: 20-30° is a less strong tool suitable for small parts where a fine surface finish is needed.

2. Cutting Rake VS Material

- 0° for short-chipping materials

- 12° for long-chipping materials

- 20° for sticky long-chipping materials

|

3. Machining Against the Sub Spindle

Recommended inserts when part off against the sub spindle are YR, ZR and SR. For maximum stability of the part use the special toolholder WSK15EL 12Q6-2P.

4. Special Corner Alternatives

Parting off/cutoff applications sometimes demand a different kind of corner execution on the parting off/cut-off insert. WhizCut can arrange any type of corner execution. Contact your local distributor who will assist you in finding the type that best suits your needs. |

|

|

Style P, PS | Inserts

for Parting Off, straight cut

| |

|

MAX D |

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

R |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| K11ER P0,5-12 |

0,5 |

4 |

0 |

12 |

b |

b |

b |

r |

- |

- |

A5 |

| K11ER/L P0,8-12 |

0,8 |

7 |

0 |

12 |

b |

b |

b |

r |

- |

- |

A5 |

| K11ER/L P1,0-12 |

1 |

9 |

0 |

12 |

b |

b |

b |

r |

- |

- |

A5 |

| K11ER/L P1,5-12 |

1,5 |

11 |

0 |

12 |

b |

b |

b |

r |

- |

- |

A5 |

| K15ER PS0,5-12 |

0,5 |

3 |

0 |

12 |

r |

k |

r |

r |

- |

- |

A4 |

| K15ER/L P0,7-12 |

0,7 |

5 |

0 |

12 |

b |

a |

b |

r |

- |

- |

A5 |

| K15ER/L P1,0-12 |

1 |

10 |

0 |

12 |

a |

a |

b |

r |

r |

r |

A5 |

| K15ER/L P1,0-12-R05 |

1 |

10 |

0,05 |

12 |

a |

k |

a |

a |

a |

a |

A6 |

| K15ER PS1,0-12 |

1 |

6 |

0 |

12 |

r |

k |

r |

r |

- |

- |

A5 |

| K15ER P1,0-20 |

1 |

10 |

0 |

20 |

b |

k |

b |

r |

r |

r |

A5 |

| K15ER/L P1,2-12 |

1,2 |

12 |

0 |

12 |

a |

a |

b |

r |

- |

- |

A5 |

| K15ER/L P1,5-12 |

1,5 |

12 |

0 |

12 |

a |

a |

b |

r |

r |

r |

A5 |

| K15ER/L P1,5-12-R05 |

1,5 |

12 |

0,05 |

12 |

a |

k |

a |

a |

a |

a |

A6 |

| K15ER PS1,5-12 |

1,5 |

9 |

0 |

12 |

r |

b |

a |

r |

- |

- |

A4 |

| K15ER/L P1,5-20 |

1,5 |

12 |

0 |

20 |

b |

k |

r |

r |

r |

r |

A4 |

| K15ER/L P2,0-12 |

2 |

12 |

0 |

12 |

a |

a |

b |

r |

- |

- |

A4 |

| K20ER P1,5-12 |

1,5 |

16 |

0 |

12 |

r |

r |

r |

r |

r |

r |

A25 |

| K20ER P2,0-12 |

2 |

20 |

0 |

12 |

r |

r |

r |

r |

r |

r |

A25 |

| K20ER P2,5-12 |

2,5 |

20 |

0 |

12 |

r |

r |

r |

r |

r |

r |

A25 |

| K20ER P3,0-12 |

3 |

20 |

0 |

12 |

r |

r |

r |

r |

r |

r |

A25 |

|

|

Style Y | Inserts

for Parting Off, 6 ° angular

cut

| |

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

D |

R |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| K11ER/L Y1,0-12 |

1 |

9 |

0 |

12 |

b |

k |

b |

b |

- |

- |

A6 |

| K11ER/L Y1,5-12 |

1,5 |

11 |

0 |

12 |

b |

k |

b |

b |

- |

- |

A5 |

| K15ER/L Y1,0-12 |

1 |

10 |

0 |

12 |

a |

k |

b |

b |

r |

r |

A6 |

| K15ER Y1,0-12-R05 |

1 |

10 |

0,05 |

12 |

k |

k |

k |

k |

r |

r |

A7 |

| K15ER/L Y1,2-12 |

1,2 |

12 |

0 |

12 |

b |

k |

b |

b |

- |

- |

A5 |

| K15ER/L Y1,5-12 |

1,5 |

12,7 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A5 |

| K15ER Y1,5-12-R05 |

1,5 |

12,7 |

0,05 |

12 |

k |

k |

k |

k |

r |

r |

A6 |

| K15ER/L Y2,0-12 |

2 |

12,7 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A5 |

| K20ER Y2,0-12 |

2 |

20 |

0 |

12 |

r |

k |

r |

r |

k |

k |

A26 |

| K20ER Y2,5-12 |

2,5 |

20 |

0 |

12 |

r |

k |

r |

r |

k |

k |

A26 |

|

|

Style Z | Inserts

for Parting Off, 15° angular

cut

| |

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

D |

R |

8M |

C8 |

F8 |

B8 |

NF8 |

ND8 |

| K11ER/L Z0,5-12 |

0,5 |

4 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A6 |

| K11ER/L Z1,0-0 |

1 |

9 |

0 |

0 |

a |

k |

b |

b |

r |

r |

A6 |

| K11ER/L Z1,0-12 |

1 |

9 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A6 |

| K11ER/L Z1,5-0 |

1,5 |

11 |

0 |

0 |

a |

k |

b |

b |

- |

- |

A5 |

| K11ER/L Z1,5-12 |

1,5 |

11 |

0 |

12 |

a |

k |

b |

b |

r |

r |

A5 |

| K15ER Z0,5-12 |

0,5 |

5 |

0 |

12 |

r |

k |

r |

r |

- |

- |

A6 |

| K15ER Z0,7-0 |

0,7 |

5 |

0 |

0 |

r |

k |

r |

r |

r |

r |

A6 |

| K15ER/L Z0,7-12 |

0,7 |

5 |

0 |

12 |

b |

k |

b |

b |

- |

- |

A6 |

| K15ER/L Z1,0-0 |

1 |

10 |

0 |

0 |

a |

k |

b |

b |

r |

r |

A6 |

| K15ER Z1,0-0-T10 |

1 |

10 |

C=0,1 |

0 |

r |

k |

r |

r |

- |

- |

A6 |

| K15ER Z1,0-0-R05 |

1 |

10 |

0,05 |

1 |

r |

k |

r |

r |

r |

r |

A7 |

| K15ER/L Z1,0-12 |

1 |

10 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A6 |

| K15ER/L Z1,5-0 |

1,5 |

12,7 |

0 |

0 |

a |

k |

b |

b |

- |

- |

A5 |

| K15ER/L Z1,5-12 |

1,5 |

12,7 |

0 |

12 |

a |

k |

b |

b |

r |

r |

A5 |

| K15ER Z1,5-12-R1 |

1,5 |

12,7 |

0,1 |

12 |

r |

k |

r |

r |

r |

r |

A5 |

| K15ER/L Z2,0-0 |

2 |

12,7 |

0 |

0 |

a |

k |

b |

b |

- |

- |

A5 |

| K15ER/L Z2,0-12 |

2 |

12,7 |

0 |

12 |

a |

k |

b |

b |

- |

- |

A5 |

| K20ER Z2,0-0 |

2 |

20 |

0 |

0 |

r |

r |

r |

r |

r |

r |

A26 |

| K20ER Z2,0-12 |

2 |

20 |

0 |

12 |

r |

r |

r |

r |

- |

- |

A26 |

| K20ER Z2,5-0 |

2,5 |

20 |

0 |

0 |

r |

r |

r |

r |

r |

r |

A26 |

| K20ER Z2,5-12 |

2,5 |

20 |

0 |

12 |

r |

r |

r |

r |

- |

- |

A26 |

|

|

Style S | Inserts

for Parting Off, 20° angular

cut

| |

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

D |

R |

8M |

C8 |

F8 |

B8 |

| K15ER S1,0-0 |

1 |

6 |

0 |

0 |

r |

k |

r |

r |

A5 |

| K15ER S1,0-12 |

1 |

6 |

0 |

12 |

r |

k |

r |

r |

A6 |

| K15ER S1,5-0 |

1,5 |

9 |

0 |

0 |

r |

k |

r |

r |

A5 |

| K15ER S1,5-12 |

1,5 |

9 |

0 |

12 |

r |

k |

r |

r |

A6 |

|

|

Style U | Inserts

for Parting Off, 30° angular

cut

| |

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

D |

R |

8M |

C8 |

F8 |

B8 |

| K11ER/L U1,0-0 |

1 |

8 |

0 |

0 |

b |

k |

b |

b |

A6 |

| K15ER U0,5-0 |

0,5 |

5 |

0 |

0 |

k |

k |

k |

k |

A6 |

| K15ER/L U1,0-0 |

1 |

8 |

0 |

0 |

b |

k |

b |

b |

A6 |

| K15ER/L U1,0-0-R05 |

1 |

8 |

0,05 |

0 |

b |

k |

b |

b |

A7 |

| K15ER/L U1,5-0 |

1,5 |

12 |

0 |

0 |

b |

k |

b |

b |

A6 |

| K20ER U2,0-0 |

2 |

16 |

0 |

0 |

r |

k |

r |

r |

A26 |

| K20ER U2,5-0 |

2,5 |

20 |

0 |

0 |

r |

k |

r |

r |

A26 |

|

|

| |

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

D |

R |

8M |

C8 |

F8 |

B8 |

| K15EL YR1,5-12 |

1,5 |

12 |

0 |

12 |

l |

k |

l |

l |

A6 |

| K15EL YR2,0-12 |

2 |

12 |

0 |

12 |

l |

k |

l |

l |

A6 |

Style ZR | Inserts

for Parting Off Against Sub

Spindle

| |

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

D |

R |

8M |

C8 |

F8 |

B8 |

| K11EL ZR0,5-12 |

0,5 |

4 |

0 |

12 |

l |

k |

l |

l |

A6 |

| K11EL ZR1,0-0 |

1 |

9 |

0 |

0 |

l |

k |

l |

l |

A6 |

| K11EL ZR1,0-12 |

1 |

9 |

0 |

12 |

l |

k |

l |

l |

A6 |

| K11EL ZR1,5-0 |

1,5 |

11 |

0 |

0 |

l |

k |

l |

l |

A6 |

| K11EL ZR1,5-12 |

1,5 |

11 |

0 |

12 |

l |

k |

l |

l |

A6 |

| K15EL ZR1,0-0 |

1 |

10 |

0 |

0 |

l |

k |

l |

l |

A6 |

| K15EL ZR1,0-12 |

1 |

10 |

0 |

12 |

l |

k |

l |

l |

A6 |

| K15EL ZR1,0-12-R05 |

1 |

10 |

0,05 |

12 |

l |

k |

l |

l |

A7 |

| K15EL ZR1,5-0 |

1,5 |

12 |

0 |

0 |

l |

k |

l |

l |

A6 |

| K15EL ZR1,5-12 |

1,5 |

12 |

0 |

12 |

l |

k |

l |

l |

A6 |

| K15EL ZR1,5-12-R05 |

1,5 |

12 |

0,05 |

12 |

l |

k |

l |

l |

A7 |

| K15EL ZR2,0-0 |

2 |

12 |

0 |

0 |

l |

k |

l |

l |

A6 |

| K15EL ZR2,0-12 |

2 |

12 |

0 |

12 |

l |

k |

l |

l |

A6 |

Style SR | Inserts

for Parting Off Against Sub

Spindle

| |

|

|

|

CUTTING

RAKE° |

STOCK |

PRICE

GROUP |

| INSERTS |

B |

D |

R |

8M |

C8 |

F8 |

B8 |

| K15EL SR1,0-0 |

1 |

5,5 |

0 |

0 |

l |

k |

l |

l |

A6 |

| K15EL SR1,0-12 |

1 |

5,5 |

0 |

12 |

l |

k |

l |

l |

A6 |

| K15EL SR1,5-0 |

1,5 |

8 |

0 |

0 |

l |

k |

l |

l |

A6 |

| K15EL SR1,5-12 |

1,5 |

8 |

0 |

12 |

l |

k |

l |

l |

A6 |

|

|

| Inserts to be used with K-type Toolholder |

L

11

15

20 |

T

2,5

2,1

3,5 |

|

Stock status

a = Stock standard in ER and EL

b = Stock standard in ER; EL against inquiry

c = Stock standard in EL; ER against inquiry

r = Stock standard in ER only

l = Stock standard in EL only

k = ER and EL against Inquiry |

|