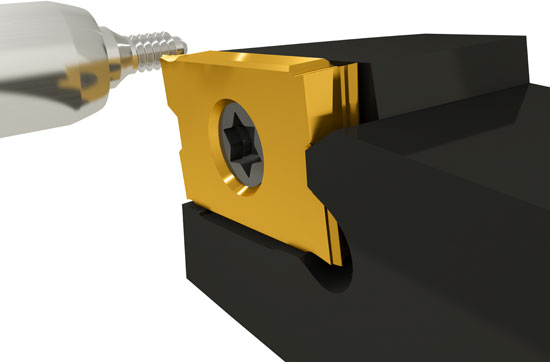

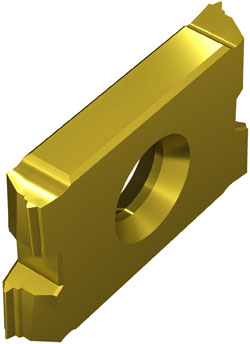

Threading Insert Geometry

All WhizThread thread turning inserts have four sharp, fully ground cutting

edges. The threading turning inserts all have a positive cutting rake ensuring the best

chip control possible when threading. The combination of a high positive

cutting rake and a ground cutting edge makes the WhizThread inserts

useful for most types of material and applications. All inserts are

developed for maximum stability and performance.

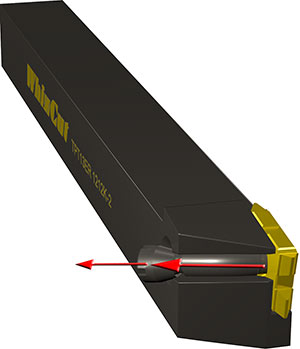

The carbide allows the insert to have a

very sharp, but still strong edge. This makes the threading inserts suitable for

materials which are difficult to machine, such as Titanium and Super

Alloys.

The combination of the best grades of carbide, the most suitable

geometries and sharp cutting edges will ensure you getting the best

tooling possible for your threading applications.

Special Threading Geometries

Our experience in the marketplace has given us a wide knowledge of

all special geometries that are needed. Therefore we are very happy to

make special forms, since we are a very flexible company and our

production is set up for us to make special inserts easily. As this is a new release we will be designing many more different standard

threading inserts.

Contact your local distributor to make sure we update with your specific

geometries first. |