|

|

WhizTwin - Double parting off insert

| |

The power and strength is where it needs to be - times two.

WhizCut has re-invented the parting off insert for the future. WhizTwin is a bold new insert that helps reduce waste material and has a cutting edge stability.

The patent pending design of WhizTwin generates a cutting edge stronger than any other and a stability not seen before. The strength and increased stability of the cutting edge is maximised with two cutting edges at the front. This lets the toolholder be clamped in a more stable position with a smaller overhang from the toolholder plate - reducing instability and vibrations which are the main chal-lenges when parting off.

Less material waste, less costs. WhizTwin is forceful, stable and overall brilliant. The narrow insert allows you to lower your production cost as you save material using it. Removing less bar material is great for you and also for the environ-ment. It’s a win win - with WhizTwin. |

|

|

| |

Power up your parting

off with WhizTwin |

- More stability, less vibrations: with two cutting edges at the front. The holder can be clamped closer to the tool plate.

- Longer tool life: thanks to the stability of the insert and cutting edge.

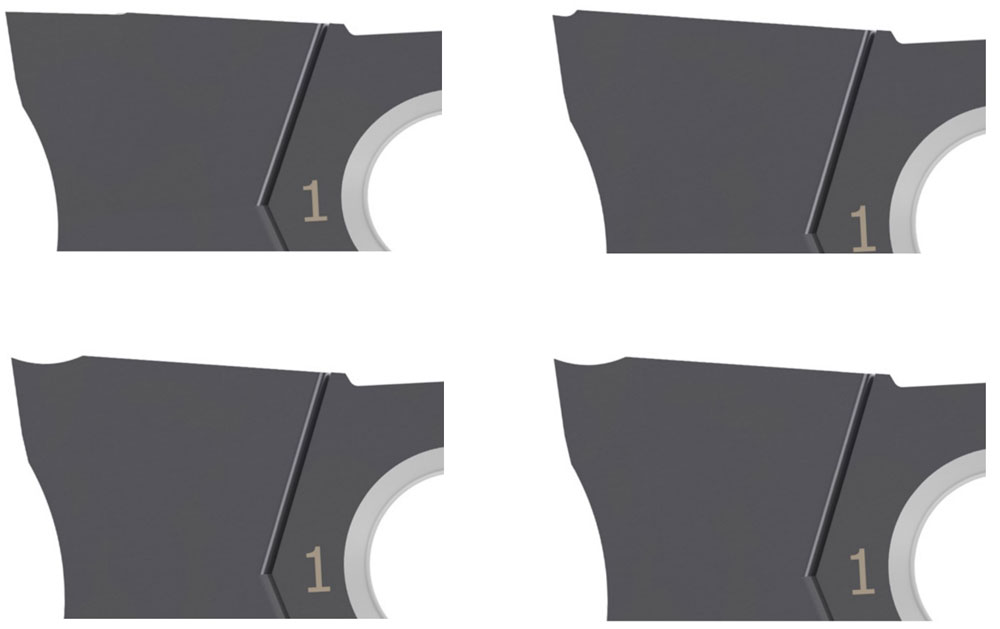

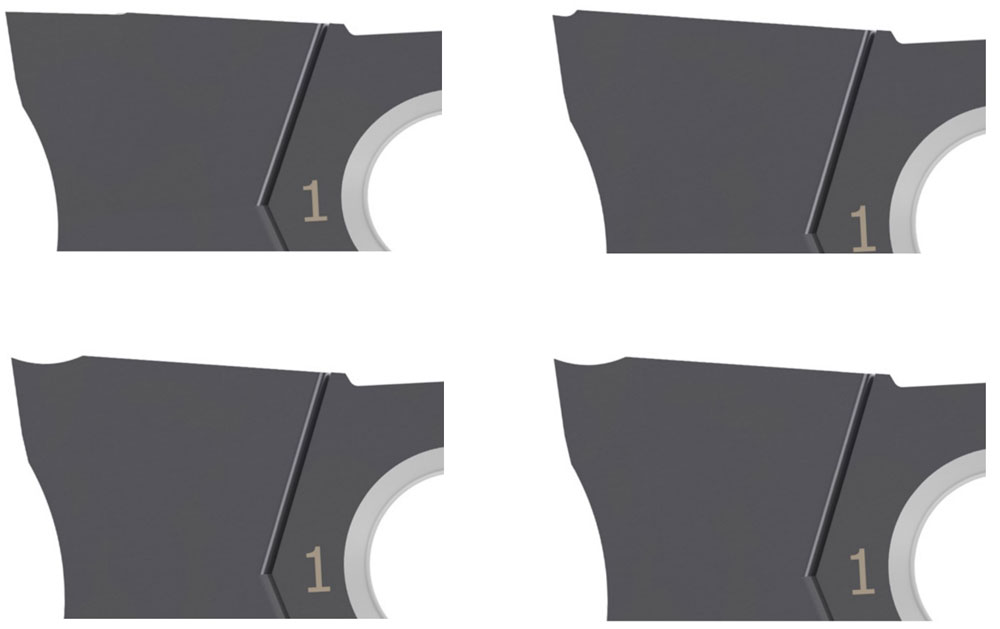

- Control those chips: with a choice of four different chip control and cutting rakes to optimise performance for most applications.

- Save material and barstock: as the WhizTwin insert is more stable than ordinary parting off inserts, it is possible to use a more narrow part off.

- Full range: of parting off / grooving tools with choices from 0,5-2 mm and extra long 0,5 mm insert - that parts off 13 mm.

- New carbide grade 7: is an outstanding carbide grade that is extremely hard and tough. Available in all five grades: 7M, F7, B7, T7, ND7.

|

|

| |

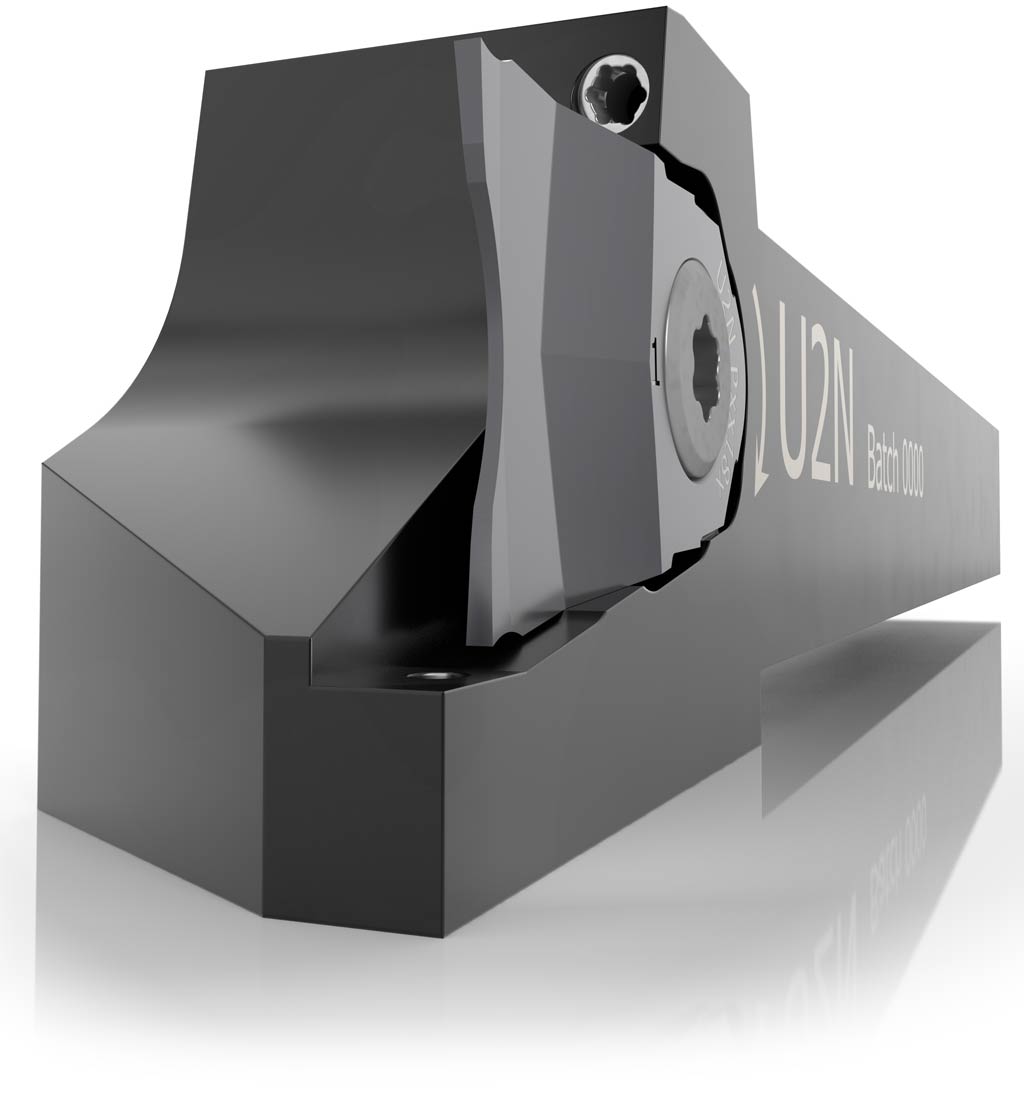

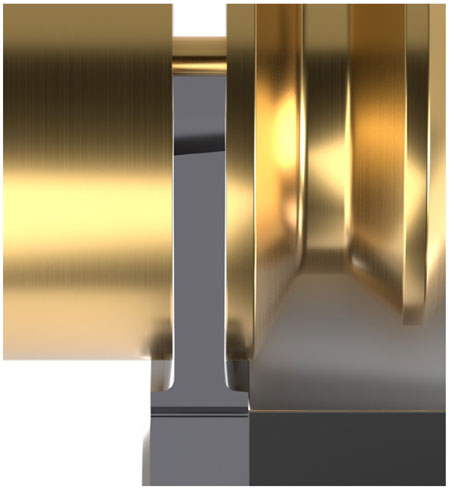

Index from both sides of the holder - as the WhizTwin screw has a double torx. |

|

|

| |

Great insert stability for parting off

|

|

| |

WhizTwin |

Converntional |

|

| |

|

|

| |

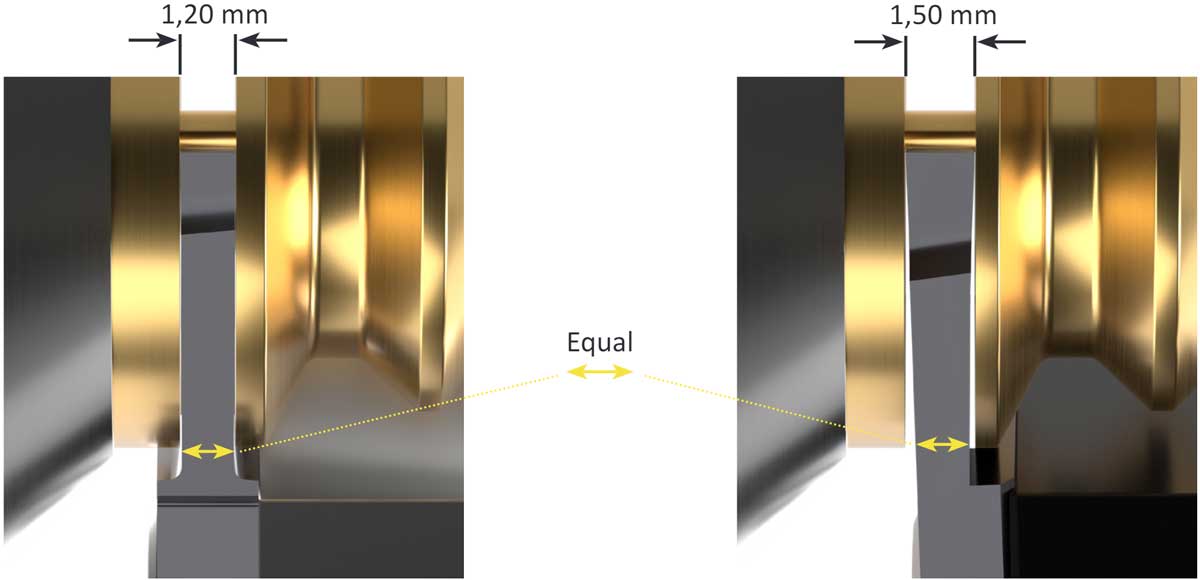

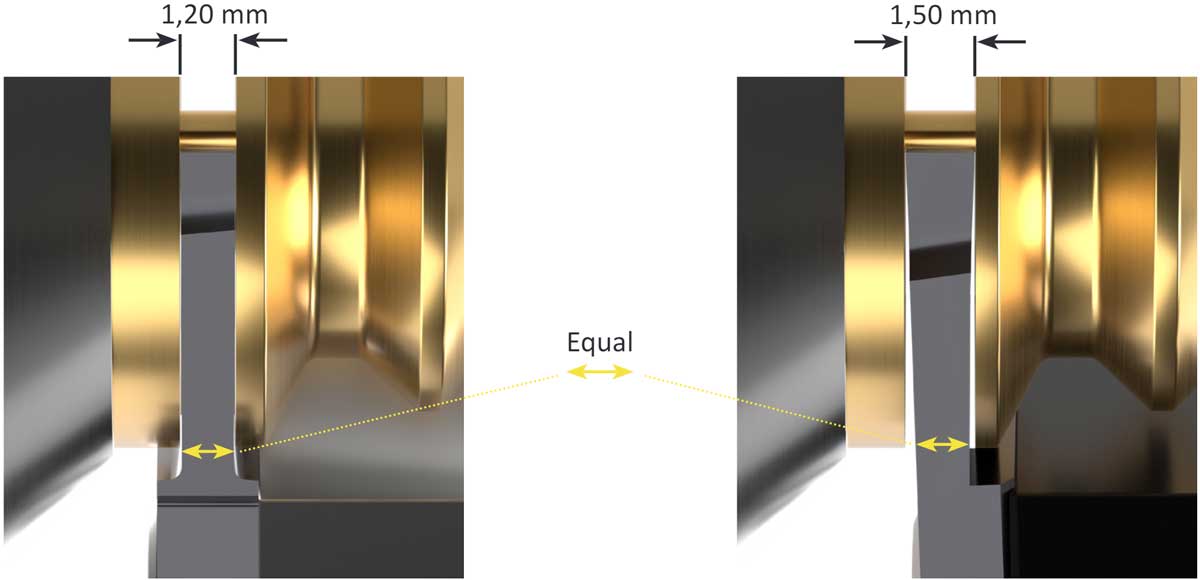

WhizTwin insert: optimizes cutting geometry and relief around and under the cutting edge which boosts mass and stability. The stability of a WhizTwin 1,2 mm part off insert achieves the same result as a 1,5 mm wide conventional insert from the top – and is considerably stronger below |

|

| |

|

|

| |

Strong, fast and tough

|

|

| |

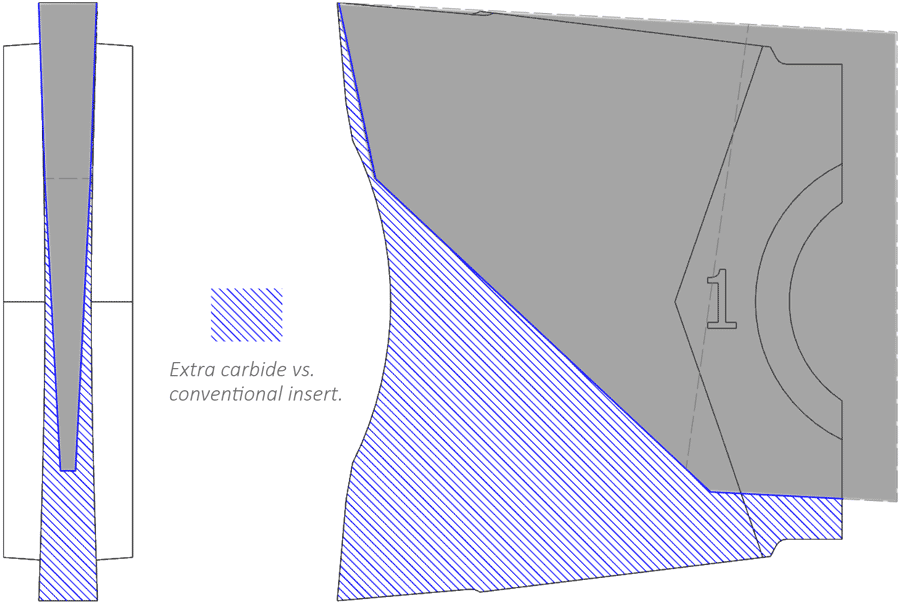

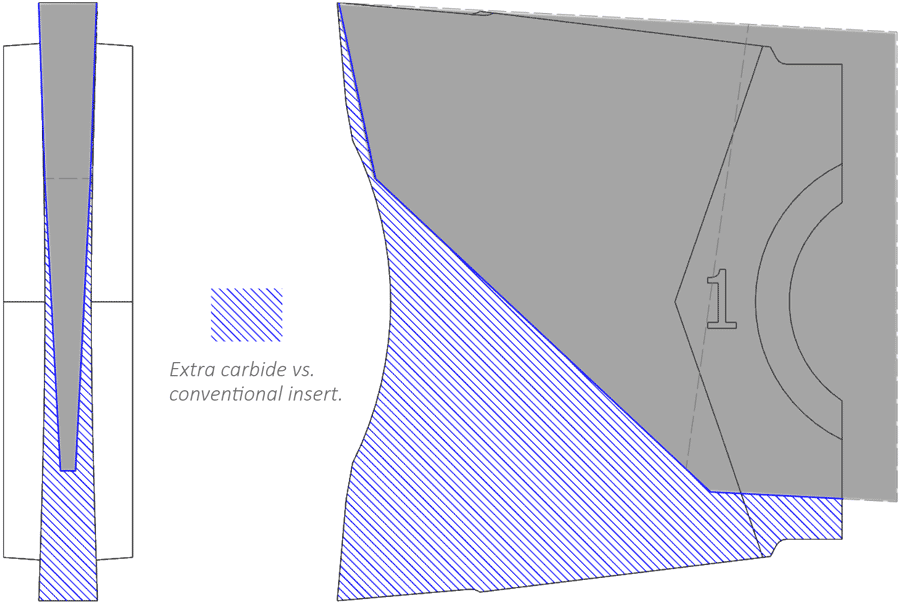

The WhizTwin design utilizes the two cutting edges to build up an extra strength under and around the cutting edge. Get longer too-life and more stable parting off – the patent pending design gives the WhizTwin insert a bigger carbide mass under the cutting edge. A 1,2 mm insert is considerably stronger than a 1,5 mm conventional insert. The strength of a 1 mm part off is the same as a 1,5 mm conventional. WhizTwin represents a new range of carbide grades developed for faster and tougher machines and materials, grade 7. |

|

| |

|

|

| |

The blue zones shows WhizTwin and the extra carbide, under the cutting-edge. Grey zones are con-ventional parting off inserts. |

|

| |

|

|

| |

Carbide grades

WhizTwin represents a new range of grades developed for faster and tougher machines and materials. The new grade 7 has proven to be an outstanding carbide that gets the hardness similar to the 8 series and at the same time is tough like the 9 series. The inserts are available in four grades: 7M, F7, B7, T7, ND7. |

|

WhizGuide - Select the ideal parting off insert

| |

1. Cutting rake

- 2° range, flat design, for soft short chipping materials and really tough materials.

- 7° range, for steel applications, where maximised corner strength and a chip control is needed. For alloyed steels, super alloys, hardened materials. Honed cutting edge only.

- 12°, universal chip control that works in most materials. Excellent in unalloyed steels, stainless steel, and titanium.

- 18°, the most steep cutting rake, with a soft chip control. Perfect for any material that has problems with built up edge, chippacking. Perfect for 316L 400 series stainless, titanium in good conditions (vibration free).

|

|

|

| |

2. Point angle vs possibillites

- Style P 0°, for most applications when a subspindle is used. This also gives the strongest tool.

- Style Y 6°, for tough applications with subspindle.

- Style Z 15°, allround angle. with or without subspindle,

nice clean part offs.

- Style U 30°, perfect for parting off without subspindle and small parts. Gives an excellent surface finish.

|

|

|

| |

3. Corner alternatives

- Most inserts are available with sharp or radius corners.

|

|

|

| |

Tool holders |

|

|

| |

WhizAdjust - center height adjustable holder |

WhizHip - coolant through holder |

|

| |

|

Available in most versions.

|

|

| |

Right hand holder

|

Left hand holder

|

|

| |

| |

Easy access - All screws have a torx in both ends and can be assembled from both sides of the holder. |

|

|

|

|

|

|