WhizTwin Parting-off inserts

| |

WhizGuide - Select the ideal parting off insert |

|

|

| |

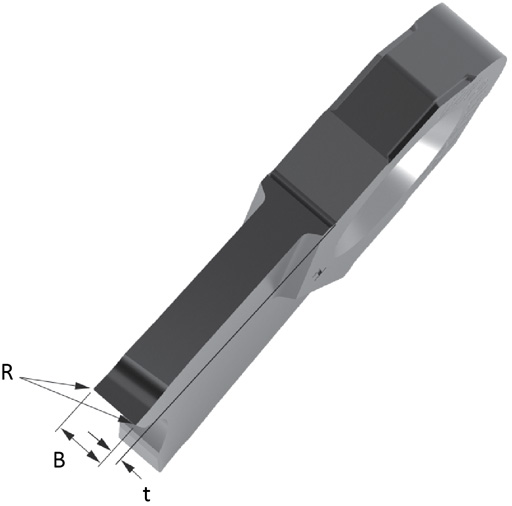

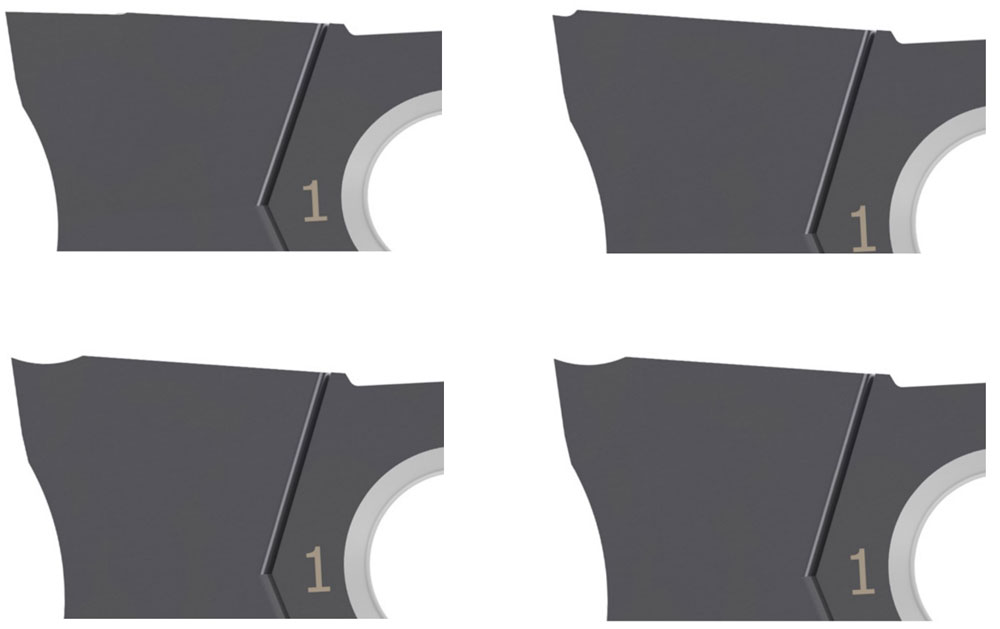

1. Straight or angled part off

- Style P: 0° gives the strongest tool. Suitable with use of sub spindle.

- Style Z: 15° Suitable to be used without a sub spindle or when parting off with the centre hole.

|

|

|

| |

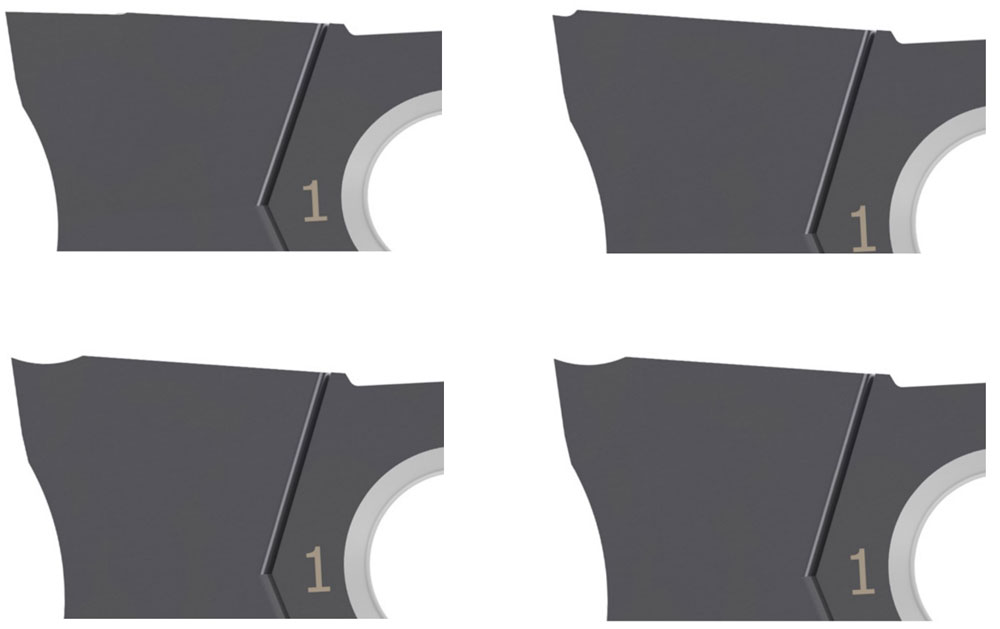

2. Cutting rake options

- 2° range, flat design, for soft short chipping materials, really tough materials and very small parts.

- 7° range, for steel applications, where maximised corner strength and a chip control is needed. For alloyed steels, super alloys, hardened materials. Honed cutting edge only.

- 12°, universal chip control that works in most materials. Excellent in unalloyed steels, stainless steel, and titanium.

- 18°, the most steep cutting rake, with a soft chip control. Perfect for any material that has problems with built up edge, chippacking. Perfect for 316L 400 series stainless, titanium in good conditions (vibration free).

|

|

|

| |

3. Corner alternatives

- Most inserts are available with sharp or radius corners.

|

|

|

| |

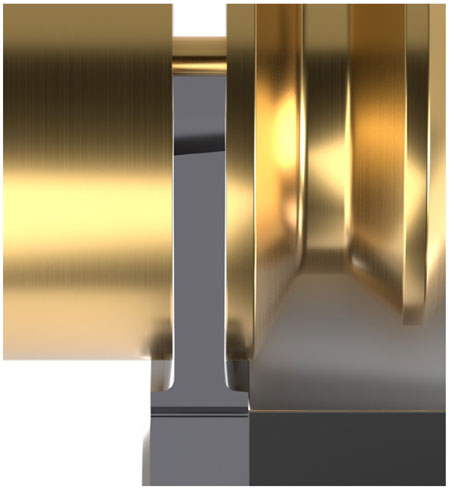

4. Make it stable

- Clamp the tool holder so the cutting edge is as close to the tool plate as your setup can allow.

- Choose as short MAX Ø insert as possible.

|

|

|

| |

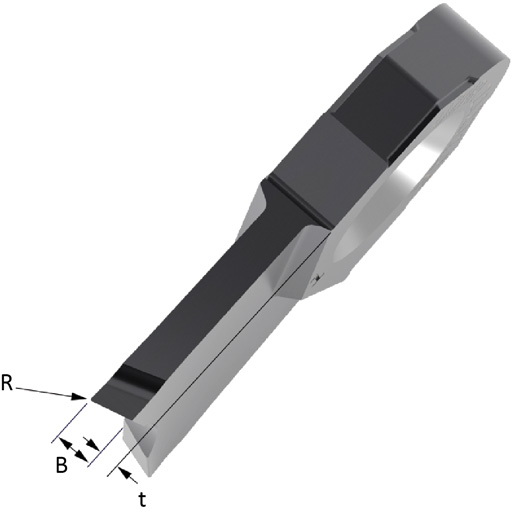

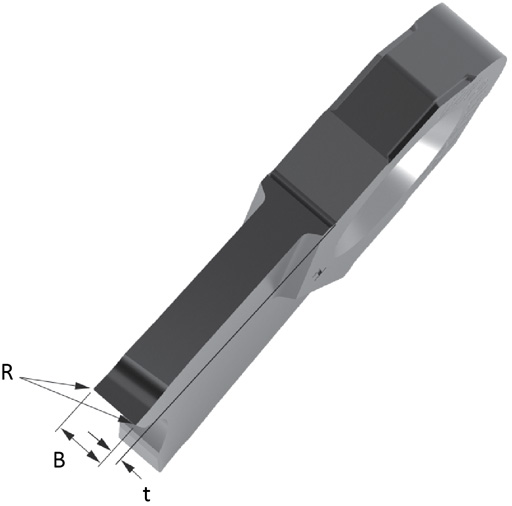

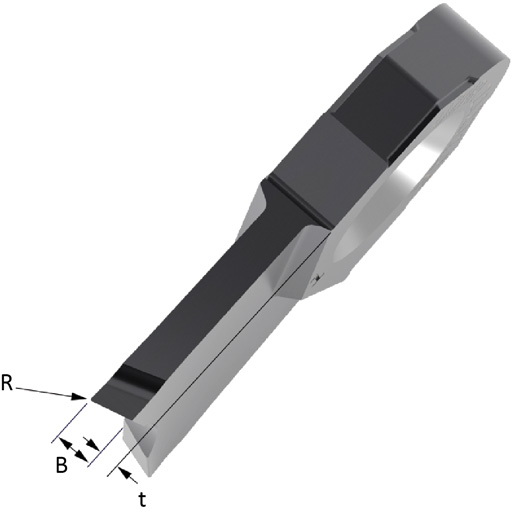

WhizTwin nomenclature

U2NR Z1,0J-12R

- U2 = insert size

- N = Neutral, NR = Neutral insert right hand geometry

- P/Z front angle

- 1,0 = Cutting width

- Max part off B = 4, C = 6,4, E = 8, G =1 0, J = 13

- -12 Cutting rake

- R = Radius

|

|

|

Style P| Straight grooving and parting off

| INSERT |

B |

C-rake |

R |

MAX Ø |

t |

7M |

F7 |

B7 |

T7 |

ND7 |

PG |

| U2N P0,3B-12 |

0,3 |

12° |

0 |

4 |

0,95 |

E |

- |

E |

- |

- |

A6 |

| U2N P0,5C-2 |

0,5 |

2° |

0 |

6,4 |

0,85 |

E |

E |

E |

- |

- |

A5 |

| U2N P0,5C-12 |

0,5 |

12° |

0 |

6,4 |

0,85 |

E |

E |

E |

- |

- |

A5 |

| U2N P0,5C-18 |

0,5 |

18° |

0 |

6,4 |

0,85 |

E |

E |

E |

K |

- |

A5 |

| U2N P0,5E-12 |

0,5 |

12° |

0 |

8 |

0,85 |

E |

E |

E |

- |

- |

A5 |

| U2N P1,0G-7R |

1 |

7° |

0,05 |

10 |

0,6 |

- |

- |

- |

- |

E |

A6 |

| U2N P1,0G-12R |

1 |

12° |

0,05 |

10 |

0,6 |

E |

E |

E |

- |

E |

A6 |

| U2N P1,0J-2 |

1 |

2° |

0 |

13 |

0,6 |

E |

E |

E |

- |

K |

A5 |

| U2N P1,0J-7R |

1 |

7° |

0,05 |

13 |

0,6 |

- |

- |

- |

- |

E |

A6 |

| U2N P1,0J-12 |

1 |

12° |

0 |

13 |

0,6 |

E |

E |

E |

- |

E |

A5 |

| U2N P1,0J-12R |

1 |

2° |

0,05 |

13 |

0,6 |

- |

- |

- |

- |

E |

A6 |

| U2N P1,0J-18 |

1 |

18° |

0 |

13 |

0,6 |

E |

E |

E |

K |

- |

A5 |

| U2N P1,5J-7R |

1,5 |

7° |

0,05 |

13 |

0,35 |

- |

- |

- |

- |

E |

A5 |

| U2N P1,5J-12 |

1,5 |

12° |

0 |

13 |

0,35 |

E |

E |

E |

- |

- |

A4 |

| U2N P1,5J-12R |

1,5 |

12° |

0,05 |

13 |

0,35 |

- |

- |

- |

- |

E |

A5 |

| U2N P1,5J-18 |

1,5 |

18° |

0 |

13 |

0,35 |

E |

E |

E |

K |

- |

A4 |

| U2N P2,0J-7R |

2 |

7° |

0,05 |

13 |

0,1 |

- |

- |

- |

- |

E |

A5 |

| U2N P2,0J-12 |

2 |

12° |

0 |

13 |

0,1 |

E |

E |

E |

- |

- |

A4 |

| U2N P2,0J-12R |

2 |

12° |

0,05 |

13 |

0,1 |

- |

- |

- |

- |

E |

A5 |

| U2N P2,0J-18 |

2 |

18° |

0 |

13 |

0,1 |

E |

E |

E |

K |

- |

A4 |

|

|

Style Z| 15° parting off

| INSERT |

B |

C-rake |

R |

MAX Ø |

t |

7M |

F7 |

B7 |

T7 |

ND7 |

PG |

| U2NR Z0,5C-12 |

0,5 |

12° |

0 |

6,4 |

0,85 |

F |

F |

F |

- |

- |

A6 |

| U2NR Z0,5C-2 |

0,5 |

2° |

0 |

6,4 |

0,85 |

F |

F |

F |

- |

- |

A6 |

| U2NR Z0,5E-12 |

0,5 |

12° |

0 |

8 |

0,85 |

F |

F |

F |

- |

- |

A6 |

| U2NR Z0,5E-18 |

0,5 |

18° |

0 |

8 |

0,85 |

F |

F |

F |

K |

- |

A6 |

| U2NR Z1,0J-12 |

1 |

12° |

0 |

12,7 |

0,6 |

F |

F |

F |

- |

F |

A6 |

| U2NR Z1,0J-12R |

1 |

12° |

0,05 |

12,7 |

0,6 |

F |

F |

F |

- |

F |

A6 |

| U2NR Z1,0J-18 |

1 |

18° |

0 |

12,7 |

0,6 |

F |

F |

F |

K |

- |

A6 |

| U2NR Z1,0J-2 |

1 |

2° |

0 |

12,7 |

0,6 |

F |

F |

F |

- |

- |

A6 |

| U2NR Z1,0J-7 |

1 |

7° |

0 |

12,7 |

0,6 |

- |

- |

- |

- |

F |

A6 |

| U2NR Z1,5J-12 |

1,5 |

12° |

0 |

12,7 |

0,35 |

F |

F |

F |

- |

F |

A5 |

| U2NR Z1,5J-12R |

1,5 |

12° |

0,05 |

12,7 |

0,35 |

F |

F |

F |

- |

F |

A5 |

| U2NR Z1,5J-7 |

1,5 |

7° |

0 |

12,7 |

0,35 |

- |

- |

- |

- |

F |

A5 |

| U2NR Z2,0J-12 |

2 |

12° |

0 |

12,7 |

0,1 |

F |

F |

F |

- |

F |

A5 |

| U2NR Z2,0J-7 |

2 |

7° |

0 |

12,7 |

0,1 |

K |

K |

K |

- |

F |

A5 |

|

|

|