WhizThrill Solid Carbide Micro Metric Thread Mills

WhizThrill Micro Thread Mill Advantages

- Unique shank design: with increased stability.

- B9 grade for extra edge sharpness. Excellent for demanding materials such as Titanium and 316/316L

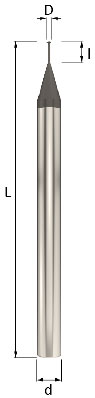

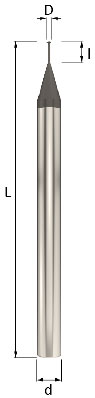

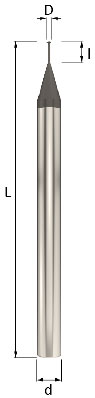

- 15° angle from minor diameter to shank.

- Available in many different lengths for each size.

- Down to M1: full profile, with minimal cutting forces gives great surface finish and longer tool life.

- Partial Profile thread mills from M0,5.

|

|

Selecting the Correct Micro Thread Mill

1. Partial Profile VS Full Profile

- Partial profile thread mills are better for long threads, tougher materials, and unstable machining conditions.

- Full profile thread mills are better when tight tolerances of major and minor is required. Cycle time should be reduced, and a completely burr free part is the needed.

2. Grade VS Material

- WhizThrill have an uncoated grade 9M, a sub-micron carbide ISO K20-K30. Performs well in soft materials where no coating is needed.

- B9 is an AlCrN coating which gives an extra edge sharpness. Tool life will be 4-5 times longer in for example titanium compared with an uncoated tool.

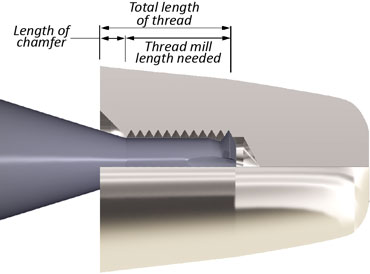

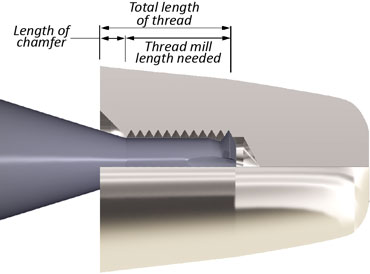

3. Determine Length

- Micro thread mills lose a lot of rigidity with increased length. Therefore, always choose the shortest possible tool.

- WhizThrill has a 15° exit angle from the minor dimension (D) to shank (d). When possible, make the chamfer before thread milling so that you can calculate the length of the thread from the end of the chamfer.

|

|

|

Partial Profile Thread Mills |

|

NS | Micro Partial Profile 60° Thread Mills

M

Course |

M

Fine |

S&UNM |

|

|

|

|

Flutes |

|

|

Stock |

Price

group |

| UNC UNF |

Thread Mill |

d |

D |

I |

L |

9M |

B9 |

| M0,5 |

M0,5 |

0,5 |

#0000-160 |

NS03003C1.3 P60 |

3 |

0,37 |

3 |

1,3 |

39 |

b |

b |

T2A |

| M0,6 |

M0,6 |

0,6 |

|

NS03004C1.5 P60 |

3 |

0,44 |

3 |

1,5 |

39 |

b |

b |

T2A |

| M0,8 |

M0,8 |

0,8 |

#000-120 |

NS03005C1.4 P60 |

3 |

0,57 |

3 |

1,4 |

39 |

b |

b |

T2 |

| M0,8 |

M0,8 |

0,8 |

#000-120 |

NS03005C2.0 P60 |

3 |

0,57 |

3 |

2,0 |

39 |

b |

b |

T2 |

| M0,8 |

M0,8 |

0,8 |

#000-120 |

NS03005C2.7 P60 |

3 |

0,57 |

3 |

2,7 |

39 |

b |

b |

T2 |

| M1,0 |

M1,0 |

1,0 |

|

NS03007C1.1 P60 |

3 |

0,7 |

3 |

1,1 |

39 |

b |

b |

T2 |

| M1,0 |

M1,0 |

1,0 |

|

NS03007C1.7 P60 |

3 |

0,7 |

3 |

1,7 |

39 |

b |

b |

T2 |

| M1,0 |

M1,0 |

1,0 |

|

NS03007C2.1 P60 |

3 |

0,7 |

3 |

2,1 |

39 |

b |

b |

T2 |

| M1,0 |

M1,0 |

1,0 |

|

NS03007C2.5 P60 |

3 |

0,7 |

3 |

2,5 |

39 |

b |

b |

T2 |

| M1,0 |

M1,0 |

1,0 |

|

NS03007C3.2 P60 |

3 |

0,7 |

3 |

3,2 |

39 |

b |

b |

T2 |

| M1,2 |

M1,2 |

1,2 |

#00-95< |

NS03009C2.0 P60 |

3 |

0,9 |

3 |

2 |

39 |

b |

b |

T2 |

| M1,2 |

M1,2 |

1,2 |

#00-95< |

NS03009C2.9 P60 |

3 |

0,9 |

3 |

2,9 |

39 |

b |

b |

T2 |

| M1,2 |

M1,2 |

1,2 |

#00-95< |

NS03009C3.9 P60 |

3 |

0,9 |

3 |

3,9 |

39 |

b |

b |

T2 |

| M1,4 |

M1,4 |

1,4 |

|

NS03010C2.2 P60 |

3 |

1,03 |

3 |

2,2 |

39 |

b |

b |

T2 |

| M1,4 |

M1,4 |

1,4 |

|

NS03010C3.3 P60 |

3 |

1,03 |

3 |

3,3 |

39 |

b |

b |

T2 |

| M1,4 |

M1,4 |

1,4 |

|

NS03010C4.4 P60 |

3 |

1,03 |

3 |

4,4 |

39 |

b |

b |

T2 |

| M1,6 |

M1,4x0,2 |

|

#0-80 |

NS03011C2.5 P60 |

3 |

1,16 |

3 |

2,5 |

39 |

b |

b |

T2 |

| M1,6 |

M1,4x0,2 |

|

#0-80 |

NS03011C3.6 P60 |

3 |

1,16 |

3 |

3,6 |

39 |

b |

b |

T2 |

| M1,6 |

M1,4x0,2 |

|

#0-80 |

NS03011C5.1 P60 |

3 |

1,16 |

3 |

5,1 |

39 |

b |

b |

T2 |

| M1,8 |

M1,6x0,2 |

|

#1 |

NS03013C2.8 P60 |

3 |

1,35 |

3 |

2,8 |

39 |

b |

b |

T2 |

| M1,8 |

M1,6x0,2 |

|

#1 |

NS03013C4.2 P60 |

3 |

1,35 |

3 |

4,2 |

39 |

b |

b |

T2 |

| M1,8 |

M1,6x0,2 |

|

#1 |

NS03013C5.6 P60 |

3 |

1,35 |

3 |

5,6 |

39 |

b |

b |

T2 |

| M2,0 |

M1,8 |

|

#2 |

NS03015C3.2 P60 |

3 |

1,5 |

3 |

3,2 |

39 |

b |

b |

T1 |

| M2,0 |

M1,8 |

|

#2 |

NS03015C3.8 P60 |

3 |

1,5 |

3 |

3,8 |

39 |

b |

b |

T1 |

| M2,0 |

M1,8 |

|

#2 |

NS03015C4.6 P60 |

3 |

1,5 |

3 |

4,6 |

39 |

b |

b |

T1 |

| M2,0 |

M1,8 |

|

#2 |

NS03015C5.4 P60 |

3 |

1,5 |

3 |

5,4 |

39 |

b |

b |

T1 |

| M2,0 |

M1,8 |

|

#2 |

NS03015C6.2 P60 |

3 |

1,5 |

3 |

6,2 |

39 |

b |

b |

T1 |

| M2,5 |

M2,2x0,25 |

|

#3 |

NS03019C4.3 P60 |

3 |

1,9 |

3 |

4,3 |

39 |

b |

b |

T1 |

| M2,5 |

M2,2x0,25 |

|

#3 |

NS03019C6.2 P60 |

3 |

1,9 |

3 |

6,2 |

39 |

b |

b |

T1 |

|

M2,5 |

|

#4 |

NS03021C4.9 P60 |

3 |

2,1 |

3 |

4,9 |

39 |

b |

b |

T1 |

|

M2,5 |

|

#4 |

NS03021C7.1 P60 |

3 |

2,1 |

3 |

7,1 |

39 |

b |

b |

T1 |

| M3 |

M3 |

|

#5 |

NS03023C5.4 P60 |

3 |

2,3 |

3 |

5,4 |

39 |

b |

b |

T1 |

| M3 |

M3 |

|

#5 |

NS03023C7.8 P60 |

3 |

2,3 |

3 |

7,8 |

39 |

b |

b |

T1 |

| M3,5 |

M3 |

|

#6 |

NS03026C6.1 P60 |

3 |

2,6 |

3 |

6,1 |

39 |

b |

b |

T1 |

| M3,5 |

M3 |

|

#6 |

NS03026C8.7 P60 |

3 |

2,6 |

3 |

8,7 |

39 |

b |

b |

T1 |

| M4 |

M3,5-M4 |

|

#8 |

NS0303C7.1 P60 |

3 |

3 |

3 |

7,1 |

39 |

b |

b |

T1 |

| M4 |

M3,5-M4 |

|

#8 |

NS0303C10.2 P60 |

3 |

3 |

3 |

10,2 |

39 |

b |

b |

T1 |

| M4,5 |

M4,5 |

|

#10 |

NS04036C8.3 P60 |

4 |

3,6 |

3 |

8,3 |

51 |

b |

b |

T2 |

| M4,5 |

M4,5 |

|

#10 |

NS04036C12.0 P60 |

4 |

3,6 |

3 |

12 |

51 |

b |

b |

T2 |

| M5-M6 |

M5-M6 |

|

#12 |

NS0404C10.0 P60 |

4 |

4 |

3 |

10 |

51 |

b |

b |

T2 |

| M5-M6 |

M5-M6 |

|

#12 |

NS0404C14.5 P60 |

4 |

4 |

3 |

14,5 |

51 |

b |

b |

T2 |

|

|

Full Profile Thread Mills |

|

NT-ISO M | Micro Single Tooth Full Form Thread Mills

| M coarse |

Pitch ISO |

Part number |

d |

D |

Flutes |

l |

L |

9M |

B9 |

Price group |

| M1,0 |

0,25 |

NT03007C1,7-0.25ISO |

3 |

0,7 |

3 |

1,7 |

39 |

b |

b |

T2B |

| M1,0 |

0,25 |

NT03007C2,5-0.25ISO |

3 |

0,7 |

3 |

2,5 |

39 |

b |

b |

T2B |

| M1,0 |

0,25 |

NT03007C3,5-0.25ISO |

3 |

0,7 |

3 |

3,5 |

39 |

b |

b |

T2B |

| M1,2 |

0,25 |

NT03009C2,0-0.25ISO |

3 |

0,9 |

3 |

2 |

39 |

b |

b |

T2B |

| M1,2 |

0,25 |

NT03009C2,9-0.25ISO |

3 |

0,9 |

3 |

2,9 |

39 |

b |

b |

T2B |

| M1,2 |

0,25 |

NT03009C3,9-0.25ISO |

3 |

0,9 |

3 |

3,9 |

39 |

b |

b |

T2B |

| M1,4 |

0,3 |

NT03010C2,3-0.3ISO |

3 |

1,03 |

3 |

2,3 |

39 |

b |

b |

T2A |

| M1,4 |

0,3 |

NT03010C3,3-0.3ISO |

3 |

1,03 |

3 |

3,3 |

39 |

b |

b |

T2A |

| M1,4 |

0,3 |

NT03010C4,4-0.3ISO |

3 |

1,03 |

3 |

4,4 |

39 |

b |

b |

T2A |

| M1,6 |

0,35 |

NT03011C2,5-0.35ISO |

3 |

1,16 |

3 |

2,5 |

39 |

b |

b |

T2A |

| M1,6 |

0,35 |

NT03011C3,6-0.35ISO |

3 |

1,16 |

3 |

3,6 |

39 |

b |

b |

T2A |

| M1,6 |

0,35 |

NT03011C5,1-0.35ISO |

3 |

1,16 |

3 |

5,1 |

39 |

b |

b |

T2A |

| M1,8 |

0,35 |

NT03013C2,8-0.35ISO |

3 |

1,35 |

3 |

2,8 |

39 |

b |

b |

T2A |

| M1,8 |

0,35 |

NT03013C4,2-0.35ISO |

3 |

1,35 |

3 |

4,2 |

39 |

b |

b |

T2A |

| M1,8 |

0,35 |

NT03013C5,6-0.35ISO |

3 |

1,35 |

3 |

5,6 |

39 |

b |

b |

T2A |

| M2,0 |

0,4 |

NT03015C3,2-0.4ISO |

3 |

1,5 |

3 |

3,2 |

39 |

b |

b |

T2 |

| M2,0 |

0,4 |

NT03015C4,7-0.4ISO |

3 |

1,5 |

3 |

4,7 |

39 |

b |

b |

T2 |

| M2,0 |

0,4 |

NT03015C6,2-0.4ISO |

3 |

1,5 |

3 |

6,2 |

39 |

b |

b |

T2 |

NT-ISO S, UNM | Micro Single Tooth Full Form Thread Mills

| ISO S-1501 |

UNM |

Pitch |

Part number |

d |

D |

Flutes |

l |

L |

9M |

B9 |

Price group |

| S1,0 |

1,00 UNM |

0,25 |

NT03007C2,5-S1.0UNM |

3 |

0,73 |

3 |

2,5 |

39 |

b |

b |

T2B |

| S1,2 |

1,20 UNM |

0,25 |

NT03009C2,9-S1.2UNM |

3 |

0,93 |

3 |

2,9 |

39 |

b |

b |

T2B |

| S1,4 |

1,40 UNM |

0,3 |

NT03010C3,3-S1.4UNM |

3 |

1,08 |

3 |

3,3 |

39 |

b |

b |

T2A |

NT-UN | Micro Single Tooth Full Form Thread Mills

| UNC UNF |

# |

Pitch |

Part number |

d |

D |

Flutes |

l |

L |

9M |

B9 |

Price group |

| UNF |

No. 0 |

80 |

NT03011C3,3-80UN |

3 |

1,16 |

3 |

3,3 |

39 |

b |

b |

T2A |

| UNF |

No. 1 |

72 |

NT03014C4,4-72UN |

3 |

1,45 |

3 |

4,4 |

39 |

b |

b |

T2A |

| UNC |

No. 1 |

64 |

NT03014C4,4-64UN |

3 |

1,41 |

3 |

4,4 |

39 |

b |

b |

T2A |

| UNF |

No. 2 |

64 |

NT03017C5,2-64UN |

3 |

1,74 |

3 |

5,2 |

39 |

b |

b |

T2 |

| UNC |

No. 2 |

56 |

NT03016C5,2-56UN |

3 |

1,68 |

3 |

5,2 |

39 |

b |

b |

T2 |

|

|

NM | Micro Metrical Two Tooth Thread Mills

Pitch

mm |

M

Coarse |

Thread Mill |

d |

D |

Cutting

Edges |

I |

L |

Price

Group |

| 0,4 |

M2 (1,5xD) |

NM03015C3 0.4ISO A9 |

3 |

1,5 |

3 |

3,4 |

39 |

T3 |

| 0,4 |

M2 (2,25xD) |

NM03015C5 0.4ISO A9 |

3 |

1,5 |

3 |

5 |

39 |

T3 |

| 0,45 |

M2.2 (1,5xD) |

NM03016C3 0.45ISO A9 |

3 |

1,6 |

3 |

3,8 |

39 |

T3 |

| 0,45 |

M2.2 (2,25xD) |

NM03016C5 0.45ISO A9 |

3 |

1,6 |

3 |

5,4 |

39 |

T3 |

| 0,45 |

M2.5 (1,5xD) |

NM03019C4 0.45ISO A9 |

3 |

1,9 |

3 |

4,2 |

39 |

T3 |

| 0,45 |

M2.5 (2,25xD) |

NM03019C6 0.45ISO A9 |

3 |

1,9 |

3 |

6,1 |

39 |

T3 |

| 0,5 |

M3 (1,5xD) |

NM03023C5 0.5ISO A9 |

3 |

2,3 |

3 |

5 |

39 |

T3 |

| 0,5 |

M3 (2,25xD) |

NM03023C7 0.5ISO A9 |

3 |

2,3 |

3 |

7,3 |

39 |

T3 |

| 0,6 |

M3.5 (1,5xD) |

NM03026C6 0.6ISO A9 |

3 |

2,6 |

3 |

6 |

39 |

T3 |

| 0,6 |

M3.5 (2,25xD) |

NM03026C8 0.6ISO A9 |

3 |

2,6 |

3 |

8,5 |

39 |

T3 |

| 0,7 |

M4 (1,5xD) |

NM0303C7 0.7ISO A9 |

3 |

3 |

3 |

7 |

39 |

T3 |

| 0,7 |

M4 (2,25xD) |

NM0303C10 0.7ISO A9 |

3 |

3 |

3 |

10 |

39 |

T3 |

| 0,8 |

M5 (1,5xD) |

NM04038C9 0.8ISO A9 |

4 |

3,8 |

3 |

9 |

51 |

T3 |

| 0,8 |

M5 (2,25xD) |

NM04038C12 0.8ISO A9 |

4 |

3,8 |

3 |

12,1 |

51 |

T3 |

| 1 |

M6 (1,5xD) |

NM06045C10 1.0ISO A9 |

6 |

4,5 |

3 |

10 |

64 |

T4 |

| 1 |

M6 (2,25xD) |

NM06045C14 1.0ISO A9 |

6 |

4,5 |

3 |

14,5 |

64 |

T4 |

| 1,25 |

M8 (1,5xD) |

NM0606C14 1.25ISO A9 |

6 |

6 |

3 |

14 |

64 |

T4 |

| 1,25 |

M8 (2,25xD) |

NM0606C19 1.25ISO A9 |

6 |

6 |

3 |

19,3 |

64 |

T4 |

|

|

|